What is Clay Tempered Katana: Tradition, Technique, Function

What’s in this article?

A traditionally designed Katana that has a hamon, a unique, and distinct blade pattern line, is likely to have been clay-tempered. These katanas are more authentic as Japanese swordsmiths have been using clay for differential treatment of their blades since 1000 years ago.

In this article, we explain what clay tempering means, its history, how it affects the blades, as well as the most popular clay-tempering methods and patterns today.

What is Clay-Tempering and Clay Tempered Katana?

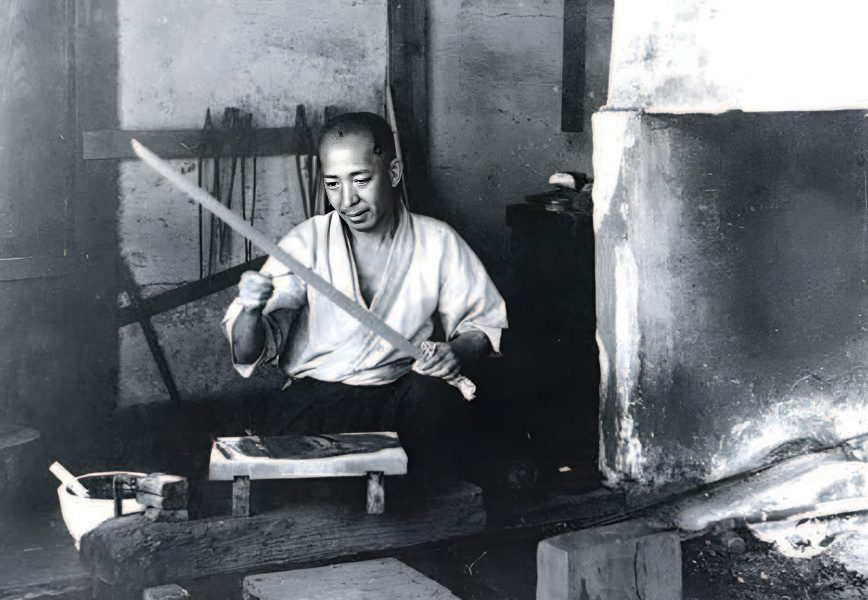

Clay tempering is a traditional Japanese method called Tsuchi-Oke to differentially harden the blades. This is traditionally done by applying clay to the blade and then carefully reheating the sword at around 1292°F (700°C), resulting in a harder edge and more flexible spine.

After the blade is reheated with the clay added on both sides, it is quenched in water or oil, allowing the Katana to obtain its unique curve while significantly hardening areas where the clay has not been applied – the edge. Meanwhile, the spine where the clay has been applied is not hardened as much, leaving it to be more flexible.

A balance is required between the brittleness and flexibility of the blade to achieve a truly functional sword. The Japanese swordsmiths have mastered this by applying a mixture of mud, ash, polishing stone powder, charcoal powder, and natural clay.

Katana Clay Tempering Process

Katana swords that have been clay tempered usually cost more due to the extra effort required. The process begins by obtaining the necessary materials and mixing it to form the clay. This mixture is then applied on both sides of the blade in a pattern of the swordsmith’s choosing before it is left to dry overnight.

Next, the process of yaki-ire starts where the blade is quenched in hot water or oil under the right temperature and time to obtain the properly hardened steel.

It is during this process where many fail especially if the blade is not properly heated throughout the blade, resulting in a cracked blade. If the quenching goes right, the yaki-modoshi begins, a process of blade tempering to relieve the clay and steel’s stress.

At this stage, although the clay-temper has been successfully applied, it isn’t really visible at this point as it is underneath the steel, requiring a careful and traditional polishing process (kaji-togi) to bring out the blade’s hamon (pattern).

Pros & Functions of Clay-Tempered Katanas

Some modern Katanas can be differentially hardened using modern techniques during the quenching process. Even in Japanese swordsmithing history, a method called Hadaki-Yaki would have resulted in a traditional hamon and different temper without the use of clay.

While that is the case, a clay-tempered Katana is more authentic as it is based on the steps followed by famous historical Japanese swordsmiths. Here are the biggest pros and functions that clay-tempered Katanas have.

- Differential Hardening – the blade is heated differently in different parts, resulting in a harder edge yet more flexible spine.

- Sharpness & Durability – the hardening allows the Katana edge (front) to cut better and become more durable as it is less likely to be damaged.

- Hamon Patterns – the clay tempering process and polishing results in a distinct and unique hamon pattern that can be chosen based on one’s personal preference

- Suguha – straight line

- Notare – irregular or wave like

- Gunome – waves

- Toranba – large waves

- Midareba – irregular lines

- Choji – flowers

- Hako – box shaped

- Mimigata – ear shapes

- Sudareba – bamboo lines

- Hitatsura – untamed lines

- Craftsmanship Tradition – the process of clay tempering is a true testament to the artisan’s skills as well as respecting history.