Damascus Katana Explained: Everything You Need to Know

What’s in this article?

A Damascus katana sword refers to a Japanese-styled katana blade once used by the samurai with a Damascus steel blade. These katana swords are very popular on the market thanks to their vibrant blade patterns, making them a perfect decorative piece for any sword display art or sword collection.

This article will explain in detail what a Damascus katana is. We will start by identifying the term and meaning behind “Damascus.” Then, we will explore the different types of Damascus katanas that one might come across and analyze their stunning characteristics. We will put the Damascus steel on a katana to the test and briefly explore its history.

What is Damascus Steel?

Damascus steel is a celebrated, mystical, and renowned sword steel type with beautifully designed and vibrant patterns across its blade. The steel doesn’t refer to a single type of sword and instead is a forging process that can be added to many different types of blades from around the world, one of which is the katana.

“Damascus” refers to the ancient steel used on many swords in Western and Central Asia. This steel type was likely replicated after the wootz steel used in India and Sri Lanka. This steel is referred to as wootz steel, but because of the trading hub in Damascus that introduced these swords to the Western cultures, the name Damascus stuck.

The process of making a Damascus steel sword was believed to have been lost over time. However, over 200 artisans worldwide have successfully recreated it to the last step. Two Damascus steel-making methods will make different Damascus katana swords.

Types of Damascus Katanas

Creating a traditionally made and real Damascus steel sword is intricate and meticulous. However, since the 1970s, a new way to bring out authentic Damascus blade patterns has been discovered, resulting in two types of Damascus katana swords.

Real Damascus Katana

A real Damascus katana sword follows the traditional Damascus forging methods. This includes using iron and steel that will be turned into a melted state, then manipulated with different heat timing, and adding various elements, bringing out the Damascus blade patterns during the blade’s solidification when it is molded into a longer blade state.

This type of Damascus katana sword is one of the rarest on the market and can only be found by directly contacting swordsmiths with experience in Damascus swordmaking. It can sometimes be called a wootz steel katana or crucible steel katana to differentiate it from the modern Damascus steel katana.

Modern Damascus Katana (Forge Welded)

A more popular type of Damascus katana sword is the forge-welded version. This Damascus katana sword will have almost the same water-wave or ripple-like patterns throughout the overall length of its blade. Making one takes two or more different steel or iron types that are then forged, welded, and folded into a single katana blade billet.

The result would be a modern Damascus katana blade with a higher amount of impurities and air gaps throughout its blade but with the visual pattern of a Damascus sword. Some modern Damascus swords, however, aren’t forge welded and can be etched in acid or lasered to paint the blade’s surface with a Damascus blade shape.

Characteristics of a Damascus Katana

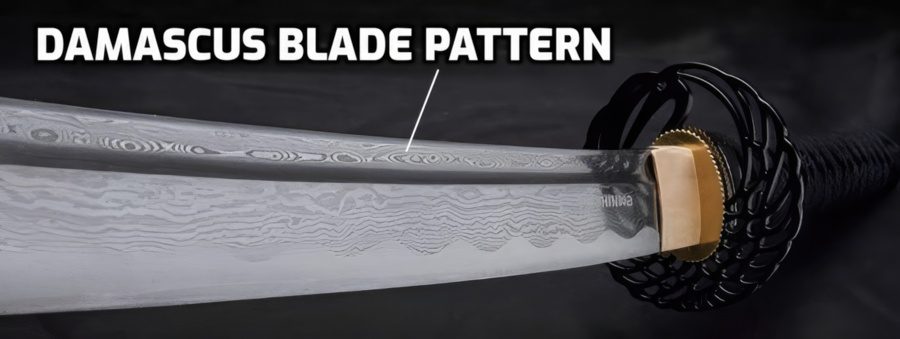

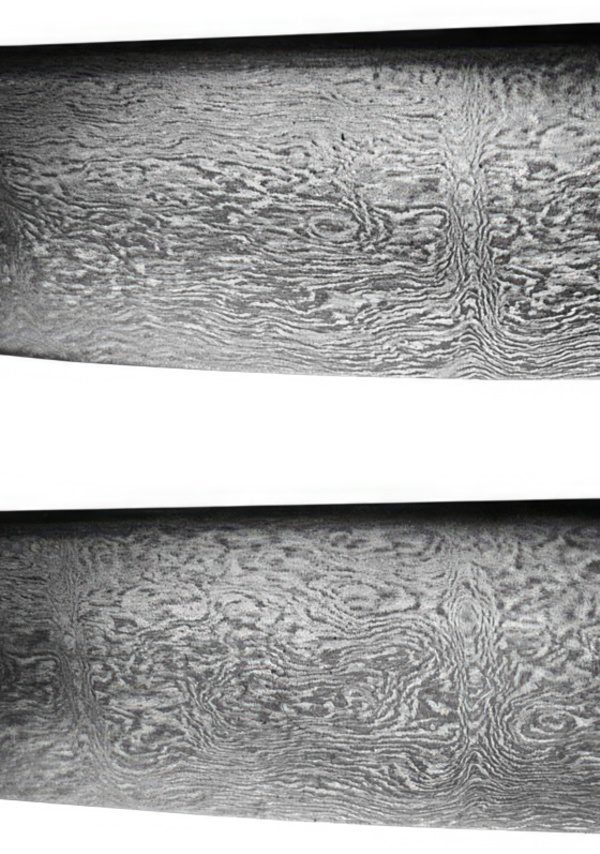

The biggest characteristic of a Damascus katana sword is its vibrant and beautiful aesthetic water-like patterns. These are mostly pronounced and visible on the Katana’s blade but can also be featured on the other metal parts of the swords, such as the handle and scabbard fittings.

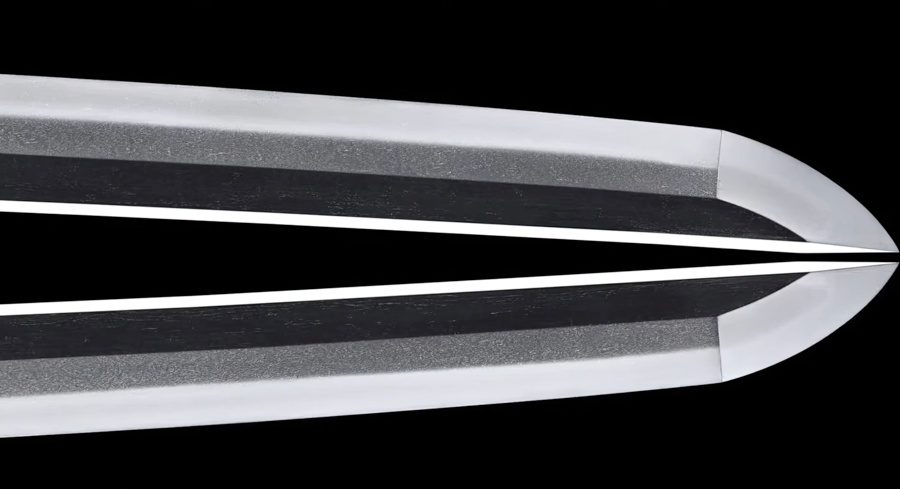

Blade

A Damascus katana samurai sword can only be called a Damascus katana if it has the Damascus patterns on its blade. These are very vibrant and can come in several different shapes. Today’s most popular are diamondback, basketweave, water drops, water waves, or inconsistent and rough patterns.

The real Damascus pattern won’t be easily visible to the naked eye and will have a dark gray color. The patterns are best seen when a flashlight is directly pointed at the blade. Still, some Damascus katanas can have a more visual and differently colored Damascus pattern on their blades.

Fittings

The Damascus pattern can be etched on the various metallic fittings throughout the katana. One of the most popular fittings to add a Damascus pattern would be the tsuba handguard and the tsuka handle, which come as a result of making it with more types of steel or simply by etching the patterns on its surface.

The blade collars, habaki, and fuchi are other fittings suitable for a Damascus pattern. These fittings can follow the same vibrant blade pattern as the blade or have their unique specific Damascus shape to make the sword more distinctive.

Is Damascus Good for Katanas??Damascus Katana Uses

Damascus steel is a good option for a katana sword to make it more visually and aesthetically pleasing. It does not make the katana stronger or give it a razor-sharp edge, as is commonly believed.

The different variations between Damascus katana swords are also based on their functionality. A Damascus katana can be battle-ready and sharpened if a good selection of high-carbon steel is used. Some good examples would be a 1060 or 1095 carbon steel, a T10 or L-6 bainite tool steel, and 5160 or 9260 spring steel. It is also crucial for the katana to have a full tang blade to be truly functional.

Both historical and modern Damascus swords aren’t better than modern mono-steel types of Katanas. Different alloy steels must be welded and folded to add the Damascus pattern to modern katana blades. These procedures add impurities in the integral structure of the blade as well as air bubbles that will make it less functional.

That is why, generally, it is considered that Damascus katana swords should only be decorative pieces. However, some artisans and quality sword manufacturers can produce high-quality Damascus handmade katanas functional for light cutting practice.

History of Damascus Katana Swords

Wootz steel swords produced in India and Sri Lanka are the predecessor and real term for modern Damascus steel. It was named Damascus by Europeans after being produced in Damascus, modern-day Syria. Damascus blades were created first around the 9th century, but there are possibilities that the Indian steel dates even further back.

During this time, Japan was significantly influenced by sword-making from other civilizations, mainly the Tang Dynasty China. With the fall of the dynasty in China, Japan’s imported swords lowered in number, and Japanese swordsmiths started producing their own unique swords with their particular methods and designs.

While Japan had many trading hubs and imported swords from other countries, there are no instances of wootz steel or Damascus steel blade patterns on a Japanese samurai sword from the past. This would explain why a Damascus katana sword is not rooted in historical authenticity, and production began in the 1970s after the forge welding Damascus method was discovered.

Today, however, Damascus katana swords are some of the most sought-after handmade Japanese blades due to the numerous depictions of them in various sorts of media, most particularly anime.

Damascus Katana vs. Japanese Katana Sword

A Damascus katana is created by Damascus steel that can be either forge welded and folded or by following the traditional and real path of element manipulation during the blade’s solidification. A traditional and authentic real Japanese katana sword called nihonto would be made out of tamahagane steel. This type of steel comes from an iron sand called satetsu, which is forged and folded into a functional high-carbon blade.

The folding process of tamahagane steel makes a unique and distinct pattern called jigane and jihada that can vary in structure, grain, and color. This differs from the Damascus pattern, which comes from forge welding different types of steel and can even be laser or acid-etched.

Other samurai swords, such as the wakizashi, tachi, katana, and even the smaller tanto swords, can be made by modern mono-steel types that can be folded to create their distinctive pattern. Hand-forged Japanese clay-tempered swords have another pattern called a hamon, which comes from differential hardening.