Are Damascus Steel Swords a Myth?

What’s in this article?

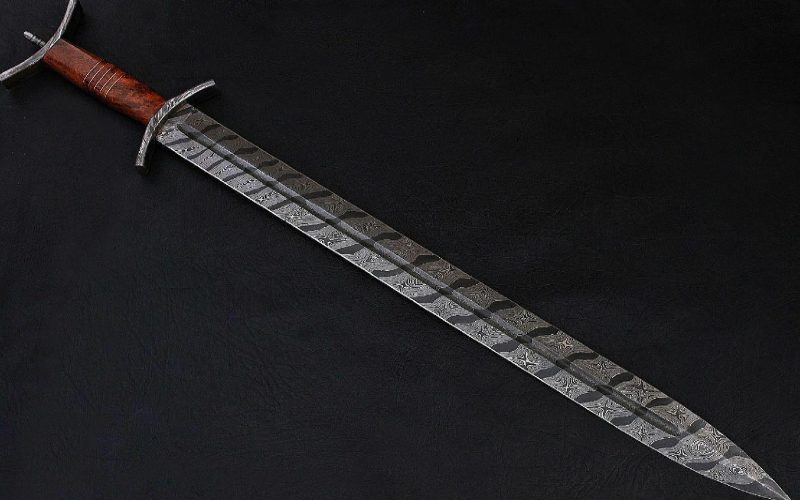

As its name suggests, Damascus steel swords are swords made with Damascus steel using an ancient technique to forge blades of different shapes and sizes. The swords originated in the Middle East or the city of Damask (modern Syria).

In this article, we will be looking at the different types of Damascus swords and their craftsmanship. We’ll discuss everything – from the origin of the Damascus steel sword, the meaning of the name, the myths and legends, and the Damascus steel sword in modern times. Does the sword still exist? How do you choose a real Damascus sword for your collection? Let’s get started.

What Is Damascus Steel?

Damascus steel is a type of forged steel smithed from ingots of Wootz steel used to create various swords. However, this art was lost in the 1700s and the modern way of forging it today is by combining two different steels into one of a kind design using the pattern welding process.

Damascus steel can be easily distinguished from other steel by its wavy patterns that are often described as being reminiscent of flowing water, giving it a sleek appearance and unique aesthetics. Damascus steel is highly prized and valuable because of its hardness and flexibility while maintaining an incredibly sharp edge.

Created by mixing two or more different types of steel together that harden and temper in the same range in order to get the desired aesthetic, making Damascus steel is a complex process that takes time and dedication.

What To Look For Before Getting a Damascus Sword?

Before buying a Damascus sword, it is advisable to consider the quality of the steel and the type of production. Other considerations include the description and types of steel mixed together.

Damascus steel doesn’t delaminate. So if you see a sword with cracks, voids, or delaminations, it is more likely that it was made with poor craftsmanship or isn’t a real Damascus sword.

Damascus swords aren’t cheap. A cheap Damascus sword may seem very beautiful but may not be very functional or real. Swordsmiths consider creating a sword from Damascus steel an art. When you consider buying a quality Damascus sword, you should expect to pay at least around $200.

How Are Damascus Swords Different?

At first glance, you will note the stainless steel in the Damascus sword. The swords go through a very long and difficult process that takes time, precision, effort, and mastering of the craft.

Damascus swords are built to last. It takes a long time to create a sword. The wavy structure makes it unique and sets these kinds of swords apart from the plain-looking type. The unique Damascus pattern is one of the most beloved arts of swordsmithing.

The biggest difference between Damascus swords and the other types of swords is the blade’s full tang. A full tang Damascus steel sword means that the blade will extend through the entire length of the handle.

Using a Damascus steel blade is also different from owning a standard type of sword or weaponry. This is more about personal taste and respect for the time and effort it takes to create such a sword and blade.

Best Damascus Swords Online

One of the biggest goals of any sword collector is to own a hand-forged Damascus steel sword. However, finding one of these most beloved pieces might be very hard as it requires a well-qualified and experienced swordsmith.

To help you find the best-crafted and handmade swords with the Damascus blade, we have composed a list of our top 5 favorite styles and types of Damascus swords.

1. Musha Damascus Dynasty Katana

The Damascus Katana blade is a Japanese sword you may see in many anime movies. The wielder, often a ninja, may have some meaningful inscription imprinted on the blade through a lengthy crafting procedure.

This Katana Damascus sword blade is manufactured by Musha and has a marble-like pattern. It is made using the traditional historical technique of creating an authentic Damascus blade. Combining various types of steel in a single blade, folding, heating, and pounding back together several times, gives a damascened high carbon blade a distinct, fingerprint-like appearance.

For around $250, this Damascus Katana sword has a sharpened blade and is battle ready. It is not solely owned for its good looks or for decoration. The blade is 29 1/4″ in length and double pegged into the tsuka (Katana’s handle).

2. Hedeby 9th Century Viking Sword

Deepeeka manufactures these swords using the traditional Damascus technique. The rippling and swirling patterns seen throughout the handmade forged blade is achieved by fusing two separate sheets of steel into a single-layered blade. The crossguard and pommel are intricately detailed and well-cast in brass with an antiqued finish. Even the wooden grip has a distinct red leather stitching to give it a vibrant appearance.

This Viking Damascus sword is a sword modeled after an actual sword discovered in the 9th century at Hedeby, Denmark that was believed to belong to a soldier or Danish noble who used it in direct battle at the northern Carolingian Border.

The length of this Damascus blade is 28 7/8” and unsharpened but battle ready. For around $430, you can have a replica of the 9th-century sword.

3. Damascus Knightly Sword – Dragon Fang

This sword’s sharpened blade is made from folded and intricately patterned Damascus steel, as are the guard and pommel. The grip is made of polished hardwood. A stitched leather scabbard with an attached belt loop and buttoned retention strap is included.

The Damascus tradition of folding layers upon layers of steel was used to create this sword. Note the rippling water and burled wood. It has the typical vibrant Damascus pattern on the blade, and a fantasy sword look. Available for around $220, this Damascus steel sword has a blade length of 32 1/2”, is battle ready and sharpened.

4. Baladay Scimitar Damascus with Steel Hilt

This Scimitar Damascus sword has a design that originated in Pakistan and owning one is therefore considered very prestigious in the sword-collecting community.

The blade of this Damascus Scimitar is unsharpened and therefore, not battle ready. It is primarily used for decorative purposes. The crossguard and pommel are made of steel, while the grip is made of polished wood.

It is manufactured by Baladay using the Damascus technique. The Damascus blade is a long 24 1/4” and can be obtained for under $200.

5. Handmade Forged Damascus Gladius Sword

This double edge hand-made Damascus Gladius sword has a high-quality Damascus steel blade made of folded steel layered by hammering and mixing more types until it reaches the desired strength and wavy structure. It comes with its own scabbard and is battle ready.

Some people might see this sword as a dagger as it is shorter than usual. The length is 18″ and weighs 3.3 pounds (1.5 kg). You can find this sword for around $120.

Taking Care Of Your Damascus Sword

Caring for a real Damascus sword requires a lot of attention and a rigorous routine to maintain its quality.

Polish

You will need to polish your Damascus sword once in a while to ensure that it will look just as good as the day it came out of the furnace. Polish your sword once a week with a soft, non-abrasive polishing cloth. If it’s wet, use a soft cloth to immediately dry your Damascus steel sword. Avoid leaving water on the surface of your sword, as it can cause Damascus steel to rust.

Clean

If you have used the sword, it is very important to clean your blade after use. Having something like food or organic matter left on the blade for too long can lead to rust. Use warm water, gentle dish soap, and then dry it immediately with a soft cloth.

Oil

If you want to maintain the look of your Damascus sword and blade for years to come, be sure to oil the steel. Oiling a Damascus steel blade can give it a deep shine that showcases its natural and beautiful pattern. If you have decorative steel blades, be sure that you oil them at least once a year.

Sharpen

To keep your Damascus blade top-notch and 100% razor-sharp, you should regularly sharpen your blade. Damascus steel is of the highest grades of blades in the world, but it is not immune to becoming dull. Usually, it is recommended to take it to a professional to be sharpened once or twice a year.

Storage

Don’t keep your Damascus sword in a leather sheath for long periods of time. Although visitors will admire your Damascus sword when it is placed in a leather sheath or scabbard, doing so will drastically speed up the rusting process.

Damascus Sword Characteristics

It is very easy to distinguish a real Damascus sword and blade from a fake one by carefully looking at its patterns and knowing the construction process that it went through. Some of the characteristics to look for include:

Patterns

The most well-known characteristic of the Damascus Swords is the distinctive appearance of the patterns.

Both varieties of Damascus steel have complex surface patterns. They are caused by the internal structural features in the steel. These patterns are the product of the steel’s unique forging processes.

Competent swordsmiths can change the patterns to recreate the complex designs found on the surface of the original, ancient, and mythical damascened steel.

There are four common patterns in the Damascus sword:

- Raindrop – Dimples are pressed or milled into the edges of the bar, then pressed and ground flat to form shapes resembling raindrops on a pond.

- Twist – The billet (solid length of the blade) is heated close to welding temperature before being twisted to create a star pattern.

- Ladder – Alternating grooves on the opposite sides of the bar are ground flat, then pressed to generate layers of stacked wave patterns.

- Random – This is where the layers remain flat and start flowing up and down to shape random wavy structures and organic patterns.

Construction

The Damascus steel blade is made by placing two or more types of carbon steel, hardening and tempering in the same range, on top of one another, tack-welding them together, and then forging them.

Then this newly created material from the two types of steel is hammered and lengthened. This process will be repeated while simultaneously adding extra steel layers. (The layers can sometimes add up to more than 200 layers!) These additional steel layers make it possible to neatly sharpen the Damascus swords.

The most important step is the heat treatment which can take a few days to finish.

The metal then gets placed in acid – a process called ‘’etching’’ to ensure that the metal shows the Damascus patterns from mixing the steel. Be sure to check out Blacksmith Quintin Middleton and how he creates a Damascus steel sword.

Length and Size

An experienced swordsmith is capable of making all types of handmade Damascus swords which can vary in shape and size.

You may find a range of Damascus steel swords, including Damascus Gladius swords, Damascus Steel Viking swords, Damascus knives, Damascus Short swords, Japanese Katana, Samurai swords, Tanto, Machetes… and various types of Damascus Medieval swords, Long swords, Samurai swords, Rapier, and so on.

The most common usage of the sword was found in the middle ages with Scimitars and Sabers, which were used widely in the Middle East. They had sharp edges with patterns added to them.

Types of Damascus Steel

There are two types of Damascus steel. The biggest difference between them is the time they were crafted, the art, and the process of creating the steel. One method is the ancient method from India, using Wootz steel and Ingot. The other is the modern method of forging two or more different types of steel together through a process called ‘etching’.

1. Crucible or Wootz Steel – Crucible, or Wootz steel, was initially made in India and Central Asia. As early as the third century AD, Wootz steel was used in making swords. After the steel was forged and heat-cycled, it acquired the well-recognizable surface “water” pattern – generally called Wootz Damascus. However, this method has been lost with time.

2. Pattern Welded Steel – A pattern welded steel, also known as modern Damascus steel, is made up of two or more different steels that have been forge-welded and twisted together to form a unique pattern. Pattern-welded steel dates back to the 2nd century AD and has been used in swords throughout Europe, including Scandinavia. Japanese swordsmiths followed a similar procedure when they created the Katana sword.

History

The original Damascus steel swords were forged near Damascus, Syria.

India first used the method of creating Wootz steel. When the trade between India and the Far East started to increase between 900 and 1750 AD, Wootz steel came into the hands of the rich Middle East, which led to the initial production of Damascus swords.

The Damascus sword spread to Europe through the Crusades in the Middle Ages. During the Crusades, the Europeans feared these swords so much that the swords gained an almost mythological reputation.

A Damascus steel blade was reported to be capable of slicing through a piece of silk as it fell to the ground. It could also chop through all the other swords that the Europeans used. It was even believed that the Damascus sword was capable of slicing through rock without losing its sharp edge!

Where Does The Name ‘Damascus’ Come From?

The origins of the term ‘Damascus’ are debatable. Although the name appears connected to Damascus-forged swords, there are several other possibilities.

- The Arabic term for water is “damas,” therefore, Damascus blades are frequently described as water swords as they have a water pattern on their surface.

- Al-Kindi, a 9th-century Muslim philosopher, referred to Damascene swords as “Damascene.”

- Al-Biruni, a scholar from the 9th century, mentioned a famous swordsmith in his writings called ‘Damaqui,’ who made the blades with crucible steel.

- It refers to the steel made in Damascus (a town in Syria) and then exported or traded from there to the world.

Legends and Myths

Damascus swords are often a part of myths and legends, yet they are real swords.

Old tales frequently mention the “quenching” or cooling process of old Damascus steel blades. According to legend, the blades’ magical strength and power came from the quenching procedure. Forgers were said to plunge heated swords into slaves to absorb their blood, transferring the strength of the slaves into the blades. Forgers were also said to “quench” the blades in dragon blood!

While the idea of quenching steel in blood may appear ridiculous, some scientists believe the nitrogen in blood may have actually improved and strengthened the sword. Who is to say?

Frequently Asked Questions

Damascus steel is shrouded in mystery and intrigue. Modern swordsmiths may use the meaning and value of this steel to their advantage to get potential buyers. The following information may help you in your decision to purchase a sword.

What Is The Difference Between a Modern and Historic Damascus Sword and Steel?

Modern Damascus steel is not the same as the original Damascus metal. While it is created using a similar process, the original Damascus steel was made from a metal known as Wootz steel.

What Is Wootz Steel, And Does It Still Exist?

Wootz is a type of steel first produced in India over two thousand years ago. Even though it was a very old type of steel, it became popular in the 3rd or 2nd century in Damascus (modern Syria).

We don’t have Wootz steel in the modern world because the techniques of creating it were lost in the 1700s. Though it no longer exists, modern blades that are composed of high-carbon steel and forged using pattern-welding come quite close.

Are Modern Swordsmiths Creating Historic Damascus Swords?

The processes of creating mythic and historical Damascus swords are no longer known. There have been several occasions where people claim to have ‘found’ a real way of creating one, but this is still yet to be true.

Is Damascus Steel The Strongest Steel?

Damascus steel is very strong, but not the strongest steel in the world. However, an experienced crafter can make a sword that can provide excellent usage for various projects and activities.

The biggest strength of Damascus steel and Damascus swords is their durability. The mixing of the metals not only makes it super sharp, but makes it much more durable. So a sharpened Damascus steel will stay sharp for much longer than any other type of steel.

Some new and current metal alloys are used alongside the Damascus sword. They are extremely strong, allowing you to work on a project that needs to withstand the most extreme conditions possible.

Damascus Steel Sword: Real vs Fake

If the Damascus sword features are exceedingly intricate, detailed, and have unnatural designs rather than the standard watery, folded, ladder, wavy, twist, raindrop, or feather patterns, it is not genuine.

You can tell whether your Damascus sword is real by looking at the consistency of the blade. A genuine Damascus steel sword will have uniform folds and patterns across the blade, cutting edge, spine, blade bolster, and tang. Folds on the sword’s pommel also indicate that the blade is pure Damascus steel.

Conclusion

Swords made from damascus steel are one of the best quality swords in the world. Not only does it look very beautiful and unique, but it also offers extreme durability and strength. Alleged Damascus swords that are too soft, fragile, or unreliable for practical usage are predominantly made of inexpensive and poorly manufactured metals. Check your buyer and craftsman to ensure you acquire a quality Damascus sword.