39 Sword Steel Types: A Guide into Metallurgical Characteristics

What’s in this article?

There are many different types of steel that can be used for a sword, each offering unique qualities and uses that may meet your needs, whether it be for powerful cutting practice (tameshigiri) or a decorative piece that is less likely to rust. The composition and craftsmanship of these steels are what sets them apart.

Understanding these differences is crucial whether you are on a sword-collecting journey or simply want to know the quality of a sword before buying it. In this article, we will explore the most popular types of steel swords that you may encounter, and delve into their usefulness, characteristics, and the best type of sword for each.

Carbon

Both flexible and hard high-carbon steel swords are excellent choices for beginners, suitable for both Japanese and Medieval European styles. These blades require careful maintenance but retain a sharp edge that resists shattering. Popular throughout history, they continue to be the preferred choice for modern blade-making.

These blades, coded as 10XX, represent plain carbon steel with the last two digits indicating the carbon content. The higher the carbon content, the harder the steel after tempering, allowing it to maintain a sharper edge. However, swords made from high carbon steel require consistent oiling to prevent rust, especially in humid areas. Although they provide excellent edge retention and flexibility, they can be challenging to sharpen.

1045

1045 steel, which contains 0.45% carbon, is generally considered the lowest carbon content suitable for a functional sword blade designed for light to moderate cutting. This steel is softer and easier for craftsmen to manipulate, resulting in swords that can be produced at a lower cost. However, its relative softness means it won’t hold an edge as effectively as higher carbon steel swords. Nevertheless, when used against appropriate targets and tempered correctly, its edge retention proves satisfactory.

Despite being marketed as an entry-level steel, a well-tempered 1045 can produce a commendable blade. Given its modern, pure steel billet construction, its quality would have been highly esteemed in past eras. Although it’s the least expensive carbon steel, it can function effectively as a battle-ready sword when crafted by a skilled blacksmith, albeit with a trade-off in edge retention.

1050 / 1055

With a slightly elevated carbon content, 1050 and 1055 high carbon steels are often chosen for bladed weapons that prioritize impact resistance and overall durability at a moderate price point. The brittleness typically associated with higher carbon steels is avoided, and additional manganese increases hardenability. With expert tempering, these steels achieve a uniformly hardened state that resists shock and impact.

Due to its higher carbon content, 1050 and 1055 blades are superior, but come at a higher price point due to its requirement of advanced swordsmith skills. These blades possess a sharper cutting edge along with heightened toughness and impact resistance, making it an excellent choice for those who can accommodate the additional expense.

1060 / 1065

The 1060 and 1065 steel types, with their carbon content at 0.60% and 0.65%, are highly favored in sword making due to balanced durability, hardness, and good edge retention. Sword manufacturers often use these steels to create practical cutting swords that prioritize durability and longevity, offering robust and reliable performance without the high cost associated with more specialized steels.

Considered the most common choice for sword production, 1060 steel provides an optimal balance between flexibility and hardness when tempered correctly. A sword made from this steel has a sturdy backbone and maintains its hard edge, providing the necessary flexibility for any blade. When crafting Katanas, this steel is usually clay tempered, resulting in a hardened cutting edge and flexible core, while creating the distinctive shape of the hamon (the blade’s temper line). This steel is a significant upgrade from 1045 and, with proper cleaning and maintenance, is an excellent choice for beginner sword enthusiasts.

1070 / 1075

1070 and 1075 high-carbon steels are known for the makings of superior blades that not only sharpen easily but also retain their edge remarkably well. Chosen when edge retention is a priority over the benefits of lower carbon steels, they offer more resilience and durability compared to their higher carbon counterparts.

In contrast to the 1060 and 1065 steel types which are general-purpose steels with a slight bias towards durability, 1070 and 1075 high-carbon steels offer a well-rounded composition leaning slightly towards a sharper edge with improved retention. If you seek a sword that maintains its edge effectively, albeit being more prone to corrosion and breakage due to higher carbon content, 1075 steel is the optimal choice.

1080 / 1085

Although less popular, 1080 high carbon steel is a noteworthy compromise, boasting superior edge retention compared to the lower carbon steels mentioned previously. However, this comes at a cost, as the brittleness typically associated with higher carbon content steels is increased.

Although it holds its edge better than the preceding steels, its heightened brittleness, while advantageous in certain situations, contributes to its lower popularity. Nevertheless, this type of steel is an excellent choice for experienced cutting practitioners who have mastered their slashing and cutting techniques.

1090 / 1095

Tempered 1095 high carbon steel with 0.95% carbon, can hold an exceptionally sharp edge, placing it at the upper end of edge retention. While tough, this steel is slightly more brittle than its lower carbon counterparts and is less forgiving with improperly executed techniques, particularly when longer sword blades are stressed.

However, this is less problematic for differentially hardened blades, which gives them the ability to retain their flexibility while maintaining the sharp edge of this high carbon steel. Other blades that benefit from this sturdy steel are shorter swords such as a Gladius or a Xiphos.

Although 1095 steel necessitates careful handling and maintenance due to its reduced corrosion resistance, it remains a suitable choice for experienced practitioners desiring a sharp, durable edge for regular, sustained use. Despite its hardness and brittleness, when properly aligned and maintained, 1095 steel offers an exceptionally sharp and functional sword edge.

1566

With a carbon content of approximately 0.60 – 0.70% and a substantial addition of manganese (0.85 – 1.15%), 1566 spring steel is often the choice of many swordsmiths. This combination results in a deep-hardening steel renowned for its high degree of hardenability. Once tempered, it exhibits a largely uniform hardened microstructure, producing a blade that’s hard, tough, and capable of maintaining a sharp edge with prolonged use, making it very popular for cutting practice.

This mix of high-carbon and manganese spring steel is not only preferred for differentially hardened Japanese and European medieval swords, but also for any functional sword due to its impressive toughness and excellent edge-holding capacity. In essence, 1566 steel offers a compelling mix of durability and edge retention, making it a remarkable choice for any type of functional sword.

6150

Renowned for its toughness and high shock resistance, 6150 steel is predominantly alloyed with chromium and vanadium. Although its carbon content is on the lower end for sword steels (0.48 – 0.53), it contributes to the material’s substantial hardenability and strength. These attributes, coupled with quality tempering, provide the steel with remarkable flexibility and resilience, often leading to its use in demanding industrial applications that require high tensile strength.

Manufacturers such as Arms & Armor and Albion Armorers favor 6150 steel due to its impressive performance characteristics. When compared to its close relative, 5160 spring steel, 6150 typically boasts higher tensile strength due to its vanadium alloying. However, it might not achieve the same level of hardness because of its slightly lower carbon content. Despite this, the overall quality of the blade heavily depends on the rigorously monitored and controlled heat treatment process in high-end sword manufacturing, resulting in higher prices.

EN9

EN9 steel, containing a carbon content of 0.50 – 0.60% and a manganese content of 0.50 – 0.80%, presents properties similar to those of 1050 or 1055 carbon steel. Like its counterparts, it can be effectively tempered and hardened, resulting in substantial durability and wear resistance. This makes it a viable option in crafting durable, long-lasting tools and equipment, aligning its performance characteristics with the well-regarded 1050 or 1055 carbon steels.

DNH7

DNH7 is a high-carbon steel akin to 1075 in composition. Its differential hardening process yields a functional blade with excellent edge retention. Due to its robustness, this sturdy, high-carbon steel is frequently utilized in Asian swords. Additionally, DNH7 can be folded and crafted to exhibit the distinctive Damascus pattern, enhancing its aesthetic appeal while maintaining its practical functionality.

Spring

Spring steel, renowned for its remarkable toughness, flexibility, and fatigue resistance, is highly favored in sword-making, especially by experienced sword enthusiasts. Each type of spring steel offers unique properties and is suitable for crafting various types of swords including samurai swords. This steel’s defining characteristic is its ability to return to its original shape, even after significant bending or twisting.

The makeup of spring steel involves low alloy, medium, or high carbon steels treated to achieve high yield strengths. It is not an easy steel type to work with, resulting in a hefty price tag, but it is worth the price-functionality ratio. This type of steel, when properly treated, can be employed and used on any type of sword in the world.

5160

Used in the production of long swords from around the world, 5160 spring steel is favored for its exceptional durability and cutting abilities. Containing approximately 0.60% carbon, 0.8% chromium, low levels of silicon, and a significant amount of manganese, this composition, coupled with meticulous differential hardening, enables the blade to perform exceptionally well.

When properly tempered, these elements lead to a deeply hardened, resilient steel structure. This is why esteemed swordsmiths like Angus Trim, Hanwei, and Tinker Pearce choose this steel for its superior shock absorption qualities which results in higher prices.

Replicating the characteristics of 1060 medium-carbon steel, the additional chromium in 5160 strengthens the blade and enhances its resistance to wear and tear. This blend makes it an ideal choice for larger, flexible blades requiring solid shock resistance. A well-maintained 5160 blade guarantees reliable durability, edge retention, and shock absorption making it an ideal steel for either a long Longsword or a curved Katana.

By replicating the characteristics of 1060 medium-carbon steel, the addition of chromium in 5160 strengthens the blade and enhances its resistance to wear and tear. This blend makes it an ideal choice for larger, flexible blades that require solid shock resistance. A well-maintained 5160 blade guarantees durability, edge retention, and shock absorption, making it an ideal steel for the makings of a longsword or a curved katana.

5166

Similar to 5160 spring steel in terms of carbon content and attributes, 5166 spring steel distinguishes itself by incorporating a manganese alloy. This addition provides the steel with additional strength and flexibility, making it slightly more wear-resistant than its 5160 counterpart which is known for its toughness.

The primary advantage of 5166 spring steel is its elevated carbon content, which is at 0.66%. This characteristic, combined with the manganese alloy, can provide increased durability and hardness, a significant advantage for those who frequently use swords.

9260

The 9260 Spring Steel, also known as Manganese Steel, contains 2% silicon, providing it with exceptional resilience against bends, even capable of returning to its original form after a 90-degree bend. Although it has a well-known reputation for its durability, it can still be broken with inappropriate use.

Since advanced craftsmanship skills are required to produce this steel, it tends to have a hefty price tag. However, for many, it offers the best price-performance ratio. It holds a sharp edge, making it effective for cutting, and its flexibility makes it ideal for both thin or broad long swords. This steel is suitable for use in rapiers, smallswords, as well as big curved swords like the Nodachi. Generally, the 9260 is considered an upgrade from the 5160 Spring Steel.

EN45

EN45 spring steel, which has a composition similar to 9260 spring steel, exhibits remarkable flexing properties due to its significant silicon content. Traditionally used in the manufacturing of automobile leaf springs, its attributes also make it an excellent choice for sword blades.

When heat-treated appropriately, EN45 mirrors the flexibility and shock resistance characteristic of well-tempered 9260 steel. Its high silicon content enables it to effectively absorb and redistribute energy, making it a dependable choice for crafting resilient, high-performance sword blades. This reinforces its standing alongside 9260 as a choice material in the bladesmithing industry.

EN42J

The EN42J is very similar to the 9260 spring steel, offering impressive flexing characteristics due to the added usage of silicon in its blade composition. This type of steel is commonly used for Japanese swords like the Katana and does not require the skills of highly experienced swordsmiths, resulting in a durable and springy material with a more affordable price tag.

65Mn

The 65Mn Chinese Steel spring alloy offers a substantial amount of resilience, thanks to its high carbon content, which ranges between 0.62 and 0.70%. It is also combined with a Manganese count of 0.9 to 1.2%. Both of these substances result in a harder and tougher blade which is still springy enough to be considered a type of spring steel. In fact, it is often compared to the 5160 Spring Steel as they have similar properties.

Tool

Tool steel blades are renowned for their unique toughness and resilience, making them some of the most cherished steel types. These steels can be forged exceptionally hard and durable, maintaining sharp edges even under considerable strain. Specially developed for tooling applications, they offer resistance to abrasion and deformation at high temperatures.

Swordsmiths prefer tool steel for its ability to produce formidable, combat-worthy blades that retain their form and potency. Although they are not as flexible and may not be suitable for some sword types, tool steel can endure significant pressure, withstand repetitive impacts, and maintain a keen edge. Ideal for broad Dadao or Falchion blades, tool steel also works well for crafting a robust and resilient Katana or Jian sword.

L6 Bainite

The L6 is one of the hardest types of steel to work with, resulting in its hefty price. However, once the construction, forging, and tempering are finished, the blade that emerges is one of the most durable and resilient of them all. A steel rich in nickel, it is exceptionally tough, resistant to damage and has tool impact resistance.

This L6 Bainite is created by repeatedly heating low-alloy or L6 steel in a very specific and hard-to-maintain temperature range. This process makes it one of the sturdiest blades on the market. Therefore, if you’re looking for a blade capable of very hard work, it’s the ideal choice. With a carbon content similar to the 1060 steel type, this means that it needs regular maintenance. It is also a frequently used for a Katana or any type of sword, but note that its price tag is usually around or over the $1,000 mark.

S7 Shock

The S7 Shock tool steel is commonly seen as an upgrade of the L6 Bainite, making it even higher on the price range. It is one of the rarest steel types as most bladesmiths do not know, or do not take it upon themselves to try to create one. One of the strongest and most durable types of steel on the market, the forged blade might not bend as much, but can take much impact.

It is commonly used for shorter swords that can do a lot of damage to any type of material. For example, it is what one would look for in survival settings or even a zombie apocalypse as it can take a lot of damage while remaining sharp and useful.

Sleipner

Sleipner is a special type of tool steel that was developed as an upgrade to D2 steel, which is commonly used for knives. It can achieve high levels of hardness and has a sturdy and stable edge that offers good wear resistance and can withstand significant impact. Although not very popular, it is sometimes used to make shorter swords.

T10

The T10 is a Chinese alloy tool steel that is often used in the production of Chinese or European swords. Roughly equivalent to the 1095 with an extra percentage of silicon to help it keep its edge retention and strength, blades made from this steel have a hard edge. Since there are various types of alloys used in the making of this steel, it can result in the blade featuring a hamon line or pattern.

The T in T10 refers to tungsten, another element that has been added to this steel type to make the blades more resistant to scratches and abrasions. The high carbon content makes it ideal for powerful cutting practices, making this tool alloy steel extremely popular in many Chinese swords such as the Niuweidao or Liuyedao.

K720

The K720 steel (also known as Bohler Tool Steel) is a high-carbon tool steel that is favored thanks to its toughness and strength. An oil-hardened steel with a chemical composition that allows it to be sharpened to a razor’s edge, it keeps its toughness even when used in cutting practices. It features a low amount of chromium content, increasing the likelihood of rusting, especially if exposed to a lot of moisture. This means it will require a lot of maintenance and care.

Stainless

Stainless steel is often used in the production of decorative pieces, especially in swords compared to knives or daggers. Although these blades often do not feature patterns, they have a high level of chromium which increases its resistance to rusting.

Excellent for display blades, it should not be used for any cutting practice as the high level of chromium makes it brittle, causing it to be broken easily if used as a functional sword. In fact, some sword enthusiasts do not even consider them as “real” swords. Smaller daggers, such as the Ko-Tanto, can feature a functional stainless steel blade, as seen in many smaller kitchen knives.

Manganese

Although Manganese swords are not very common, they can be found and hold a significant value. Not much is known about their cutting abilities, but the higher manganese content makes them brittle and easily breakable. However, this same content also makes the steel resistant and highly flexible. Therefore, it is an excellent choice for a novice swordsman who wants to use it for light cutting practice, as well as a great decorative piece.

Niolox

The Niolox is a stainless steel type which is often used to replace the ATS-34. Offering a reasonable degree of toughness and edge retention, it is great for smaller and shorter daggers or knives. Despite holding off well against corrosion, it isn’t a very popular type of steel in larger blades or knives used for cutting practice.

K120C

K120C is a type of powder steel produced in Japan under license from SSAB in Sweden. One of the main advantages of powder steels is their highly homogeneous microstructure, which enables exceptional distribution of carbon content throughout the blade. This uniform distribution contributes to consistently optimal results during the tempering process.

In terms of edge retention and durability, ASSAB K120C performs similarly to 1095 high carbon steel. The use of ASSAB K120C in blade production ensures a high degree of carbon distribution, resulting in reliable performance and excellent edge retention properties.

Q235

Q235 is a type of Chinese steel that is commonly used for producing inexpensive sword blades. It is a stainless steel that is resistant to corrosion, but it does not hold an edge and is therefore not effective for cutting practice. This type of blade is suitable for sword beginners who are looking for an affordable decoration.

3CR13

An upgrade from the Q235 is the 3CR13, which is also a type of stainless steel that is rust-resilient, but much tougher than its predecessor. It is also very affordable and makes for a great decorative blade for beginners or LARP enthusiasts.

2CR13

The 2CR13 is also very similar in composition to the previously mentioned 3CR13. However, this steel type has less carbon content and better corrosion resistance, making it closer to stainless steel. While it can hold an edge and is inexpensive, it is not used for larger swords. It is mostly useful for smaller tactical-style swords such as a Kukri or a Bowie knife.

420J2

Since the 420J2 is a type of stainless steel that is designed to resist corrosion and last for a long time, it is often used in decorative pieces. Unlike other stainless steel types, the 420J2 steel can be easily sharpened, but does not hold an edge for very long. Despite this, it is an excellent type of steel for blades that are displayed or mounted on the wall as decorative pieces.

420HC

One of the best stainless steels on the market is the 420HC stainless steel. It is commonly used for smaller daggers or kitchen knives that feature a high carbon content. This results in a blade that is heavily rust-resistant but with a sharp edge and toughness. Usually, this type of stainless steel is more expensive and used in higher-end decorative swords.

440C

The 440C stainless steel is often mislabeled on the market. Containing a high chromium content to better fend off rust, it also has a significant amount of carbon, allowing it to be sharpened and remain somewhat functional. However, this does not mean it is a battle-ready sword as it is still intended to be used as a decorative piece that can perform simple tasks such as cutting through paper, resulting in its higher price range.

AUS-6-8-10

AUS-6, a member of the AUS family of Japanese steels, is characterized by its 0.6% carbon content. It produces a tough blade, typically boasting a hardness in the mid-50s on the Rockwell scale (HRc). Although it sharpens well, it needs frequent maintenance after use.

AUS-8 is popular among custom makers and premium knife manufacturers due to its toughness, excellent edge retention, and 58-59 HRc hardness. AUS-10, on the other hand, with its higher carbon content, yields a blade hardness of 60-61 HRc while maintaining substantial toughness. While it may have slightly less corrosion resistance compared to 440C, it is compensated with a more resilient blade.

Folded

Folded swords are not a specific type of steel, but rather a product of a meticulous forging process. This involves repeatedly pounding and folding the steel to eliminate impurities and inconsistencies, resulting in a functional, durable, and flexible blade.

While many believe a sword can be folded thousands of times, as often thought of with the Katana, any fold beyond the 20th actually weakens the sword. Despite this, folded steel blades regardless of the type of sword, are highly regarded for their aesthetic appeal. However, it should be noted that they don’t possess superior strength compared to contemporary mono-steel blades. The bigger price tag comes as a result of the traditional bladesmithing process.

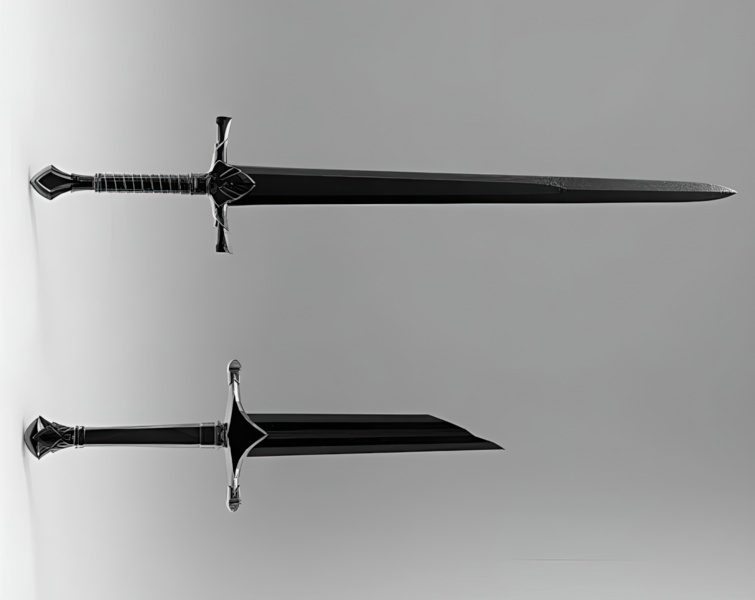

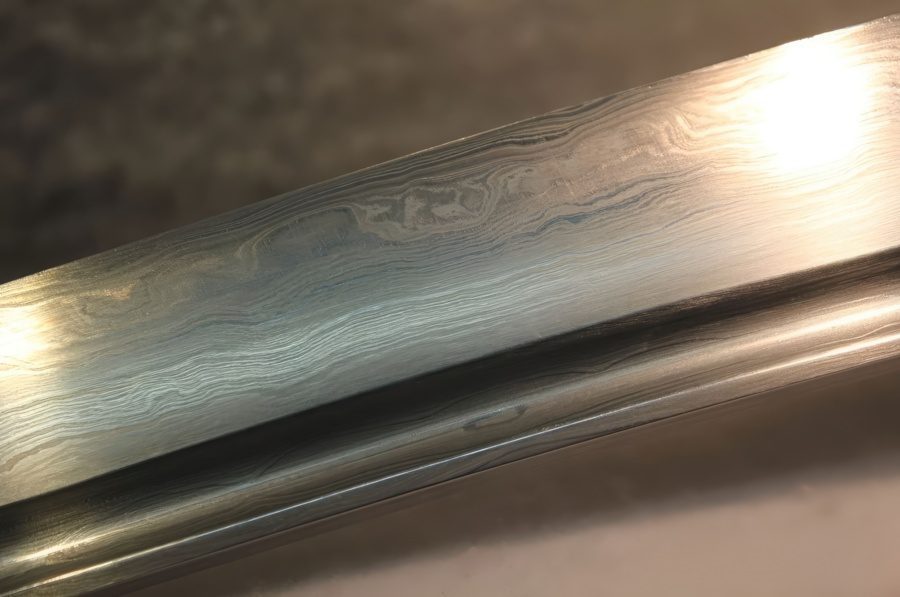

Damascus Steel

Damascus steel refers to the melding of two or more distinct steels into a singular blade. This process creates unique and vibrant patterns that are revealed through acid treatment which induces color changes in the differing steel layers. This often adds a level of mysticism, making this type of steel popular in the sword community.

Despite its allure, Damascus Steel is not superior to contemporary mono steel. With every fold of the billet or blade, there’s a risk of retained air pockets that reduce the blade’s structural integrity. Although skilled craftsmanship can mitigate this risk, Damascus blades are still technically weaker than homogeneous steel billets produced with modern metallurgical processes.

Modern Damascus steel is a favorite among collectors due to its aesthetic appeal. Highly sought after by those who seek a handcrafted and unique piece or one that reflects the appearance of a blade made using traditional skills. While it can be used as a functional blade for some cutting tests, Damascus Steel blades are best used as decorative pieces.

Tamahagane Steel

Tamahagane Steel is traditional Japanese iron sand that is transformed into blade steel through the process of smelting, folding, tempering, and polishing. Although it is one of the most expensive types of steel on the market, it is not one of the strongest, as is often mistakenly believed. This folded steel creates a beautiful pattern on the blade, but its folding process also makes it more fragile and breakable compared to modern mono-type carbon steel.

It is only commonly used for Japanese swords as it requires a very lengthy and carefully executed traditional process, resulting in hefty price tags that are usually more or around the $3,000 mark.

There are also other types of Tamahagane such as the Chinese Tamahagane steel, which can be found on Chinese swords and range around the $800 mark. The Tamahagane steel blade billets have a high carbon content throughout the blade which leads to harder and stronger cutting abilities. However, note that these blades require adequate maintenance.

Laminated

Laminated steel is a traditional Japanese method of blade construction in which panels of different steels are forge-welded to create a single blade. It is not a specific type of steel but rather a technique that optimizes the blade’s performance. Laminated steel Katana typically incorporates hard and soft steels for the edge and core, along with additional panels of other steels, resulting in a blade that combines various properties.

Historically, folding was employed to homogenize the steel by spreading out the carbon content and achieving uniform quality. Comparatively, laminating involves adhering different steels together to harness their distinct qualities, such as flexibility on the inside and a sharp edge on the outside. This technique follows a prearranged pattern of placing different steels to achieve desired characteristics.

Alloy & Other

In order to create a sword that can be sharpened and used for actual cutting, carbon is an absolute necessity. However, a blade’s effectiveness may be hindered if it is made solely from carbon steel. During the manufacturing process of a carbon blade, metal alloy is added to provide unique properties.

The inclusion of alloying elements such as silicon, manganese, and chromium can enhance the properties of steel blades beyond what carbon alone can achieve. The most popular examples of metal alloys are spring and tool steel types. These elements can improve the steel’s resistance to wear and corrosion, as well as its toughness, flexibility, and strength. There are even some alloys that can take it a step further.

San Mai

In metalwork, San Mai refers to a blade construction technique using a metal alloy. The term comes from the Japanese words “San” (three) and “Mai” (unit counter for flat objects). The technique involves forming the blade’s edge with hard steel, also known as hagane, and encasing it on both sides with softer iron or stainless steel. This tri-layered method provides a balance of both hardness and flexibility. Some examples of San Mai may feature a combination of spring steel and tool steel, making it a truly unique type of metal alloy used in blade construction.

Wootz Steel / Crucible Steel

Wootz steel, a type of blade steel characterized by a unique swordsmithing technique, was lost to history around the 17th or 18th century. The original version of what is currently referred to as “Damascus Steel” was made from wootz or crucible iron metal. Today, finding or purchasing such a blade is exceedingly rare.

Although the production technique was largely lost, some manufacturers have managed to mimic or even replicate only the distinctive patterns seen on traditional Wootz Steel. It was once considered the world’s finest steel, and although it was without a doubt superior to older steel for several centuries, tests conducted in the 19th century revealed that Wootz Blades fell short in comparison to certain European steels over time.

HWS-1S Alloy

The HWS-1S is a type of steel that is kept as a trade secret by the Hanwei sword company, and its blade composition is unknown. It is known for its performance, resilience, and edge retention, making it a popular choice for steel blades. One of its strongest traits is the differential tempering, which creates a vibrant hamon or blade pattern.

HWS-2S Alloy

Yet another type of steel from Hanwei that is kept as a trade secret, the HWS-2S alloy is a cheaper version of the previously mentioned HWS-1S. It is also differentially tempered and has varying degrees of carbon content spread unequally along its blade. Swords made from this steel are functional as a cutting sword.

Aluminum

Aluminum, a lightweight, recyclable metal, is commonly used for crafting practice swords such as the popular Japanese Iaito. Due to the availability of the material, aluminum swords are cost-effective and bear a shiny chrome finish, making them a favorite among collectors, martial arts novices, as well as in movie stunts.

However, aluminum swords come with their share of drawbacks. The metal’s susceptibility to wear means a shorter lifespan. Its inability to endure traditional Japanese heat treatment techniques also results in a duller edge. Thus, while they are excellent for beginners, their use in advanced martial arts or prolonged collection is limited.

Synthetic

Blades for synthetic swords can be constructed from synthetic materials or sheet steel. This blade style is typically employed by novices during practice and sparring because of its light weight and maneuverability. While its ease of use contributes to its security, users should nevertheless take all necessary precautions when working with synthetic steel. Synthetic swords actually lead to greater injuries in HEMA (Historical European martial arts) training because their users get complacent, assuming that the swords would not inflict any harm.

Synthetic sword blades can be constructed from synthetic materials or sheet steel. This blade style is typically employed by novices during practice and sparring as it is lightweight and increases maneuverability.

While this may be thought of as safer, one should always take the necessary precautions when working with synthetic steel as users tend to become complacent when using synthetic swords, leading to greater injuries in HEMA (Historical European martial arts) training.